Products

Tungsten Solid Carbide Rods

Carbide Rods Description

Tungsten carbide rods are widely used for creating premium solid carbide tools, such as end mills, drills, reamers, milling cutters, stamping, and measuring tools in different industries.Kedel Tool manufactures top and consistent quality carbide rods in varied grades including K20F, K25F, etc. We supply both unground and ground carbide rods. A comprehensive standard selection of tungsten carbide rods in various dimensions is available, and we also offer customization services according to your requirements. As an ISO manufacturer, Kedeltool use top-quality materials to guarantee the quality and performance of our carbide rods. With rigorous quality inspections, we can ensure consistent quality within each batch.

Kedel Carbide Rod Types

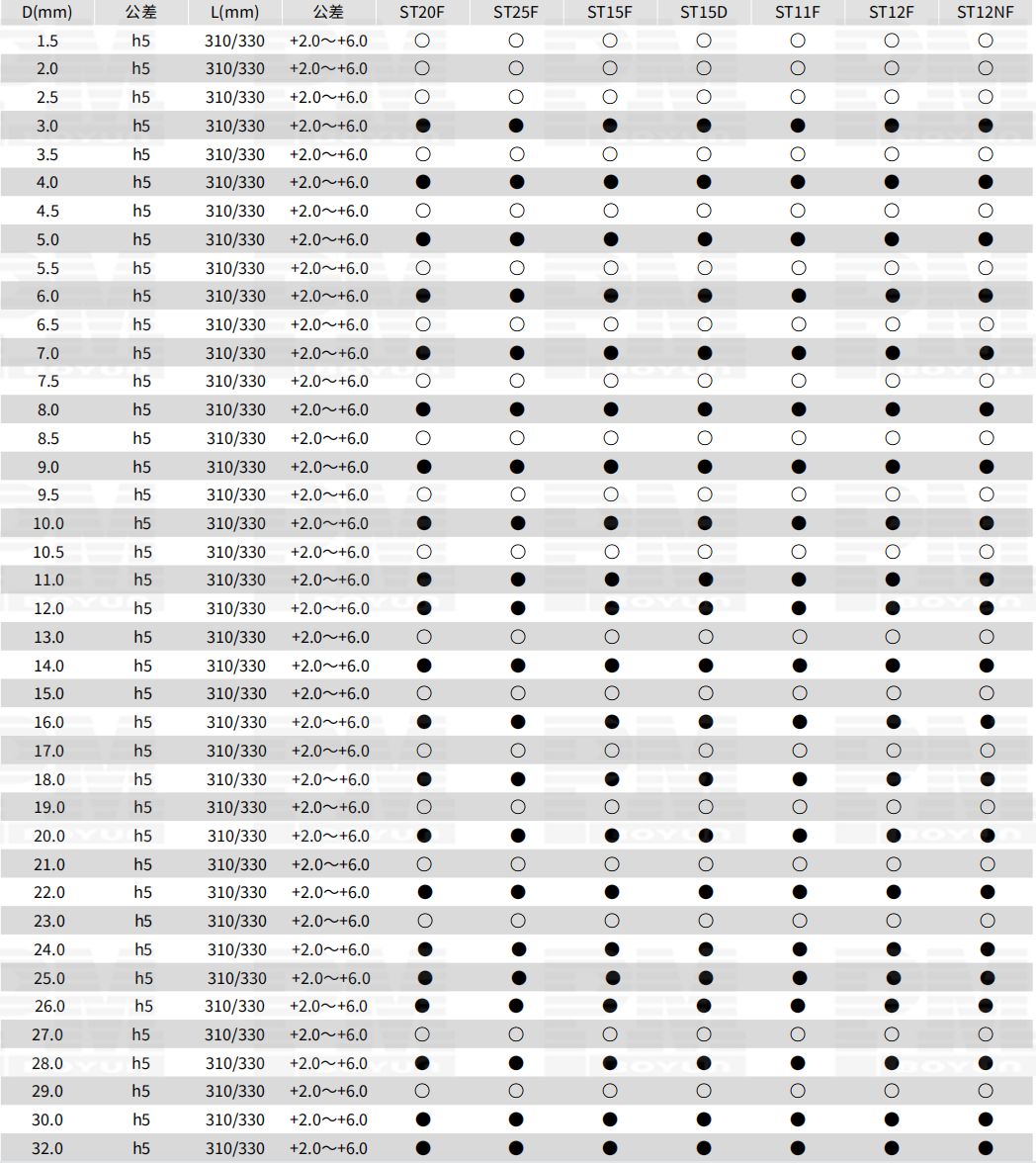

1. Solid Carbide Rods in Metrics

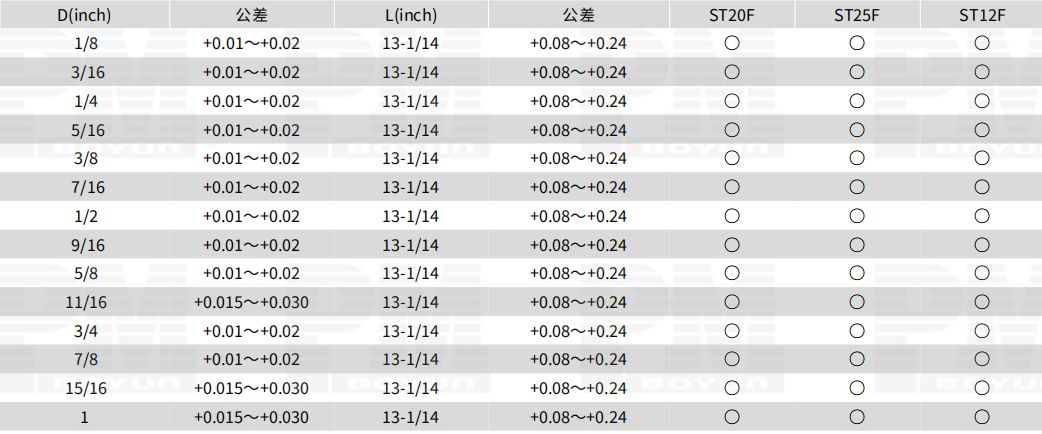

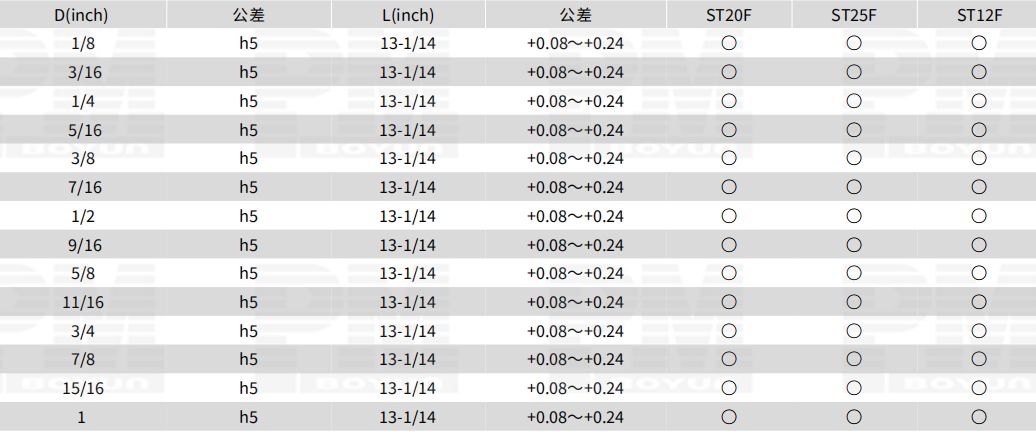

2. Solid Carbide Rods in Inches

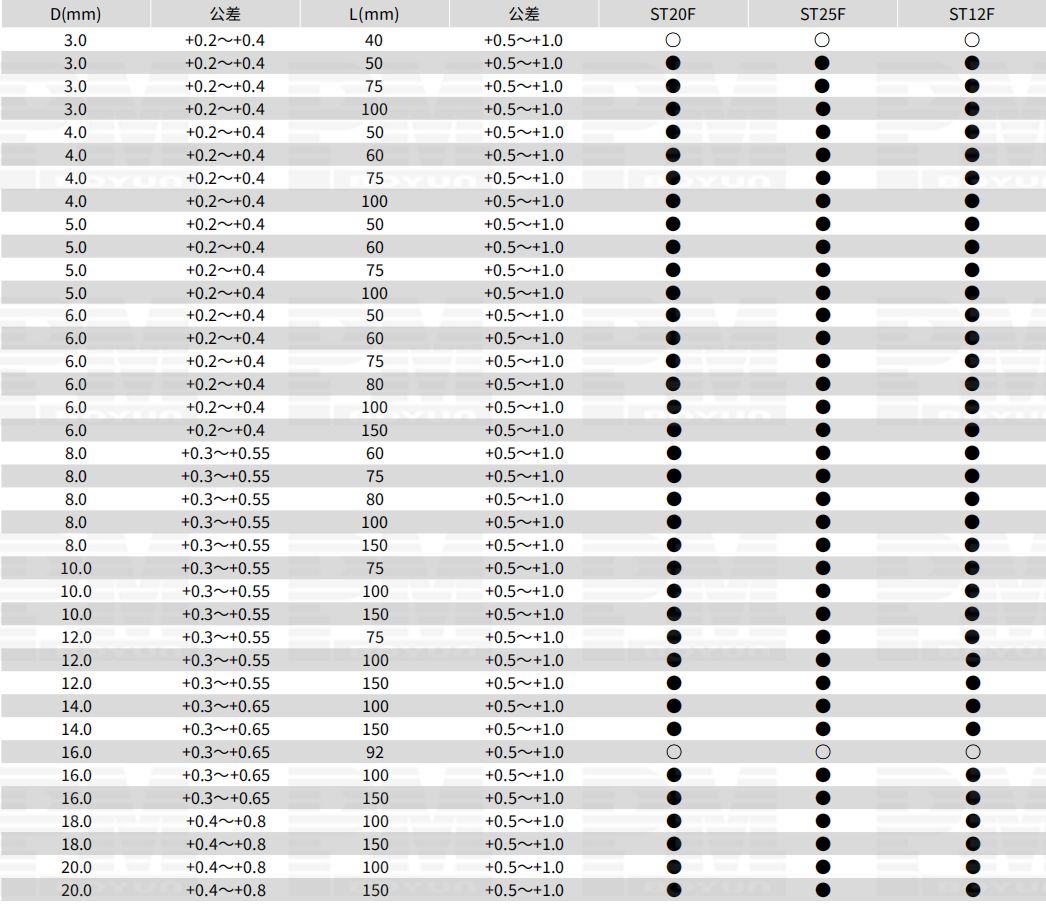

3. Drill Blanks (Chamfered)

4. End Mill Blanks (Chamfered)

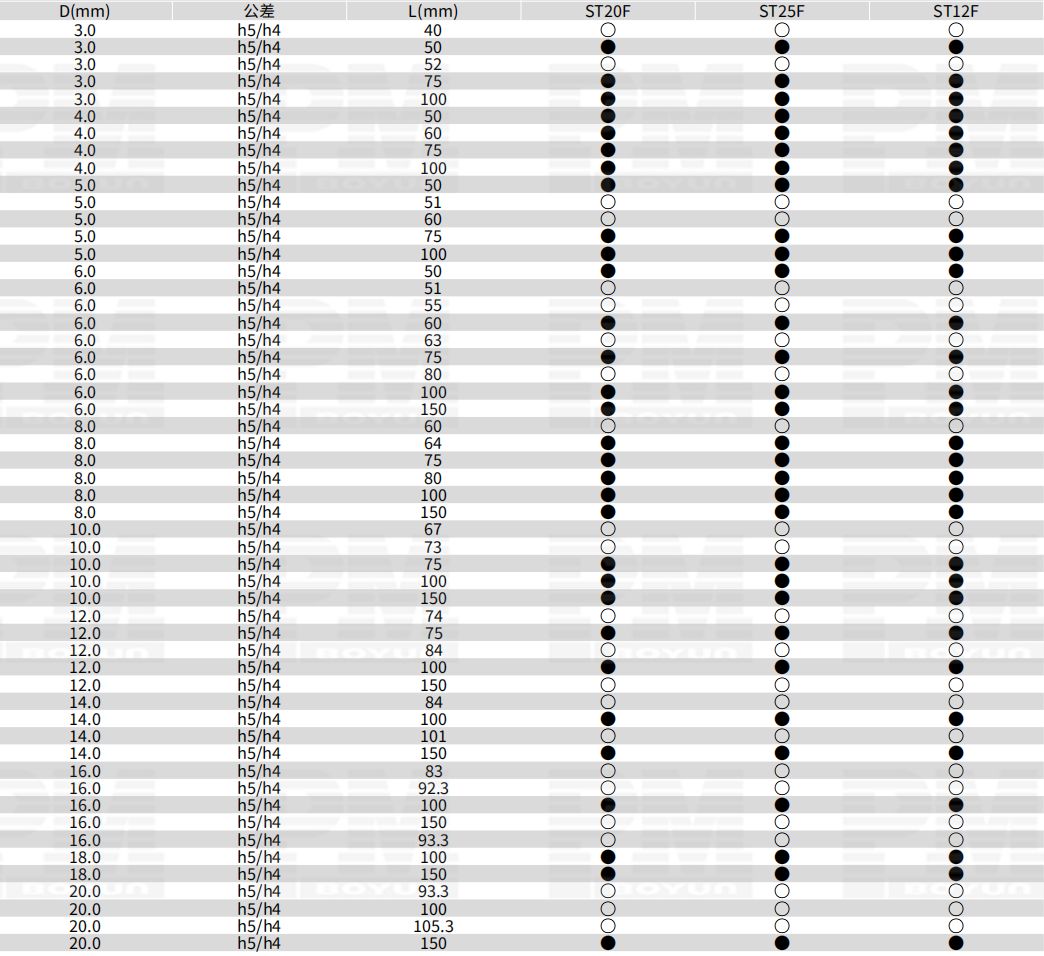

5. Carbide Rods with A Straight Central Coolant Hole

6. Carbide Rods with Two Straight Coolant Holes

Carbide Rod Characteristics

1. Made by high quality tungsten carbide superfine powder

2. Precision equipment with 10MPa HIP-Sinter stove standardized manufacture.

3. High hardness and high strength

4. Special advantages: Red hardness, wear resistant, high elasticity modulus, TRS, chemical stability, impact resistant, low dilatation coefficient, heat conduction and electric conduction same with iron.

5. Special technology: high pressure sintering of high temperature vacuum. Reduce porosity, reduce compactness and mechanical property. Various grade, types and sizes.

6. Different grade for your reference.

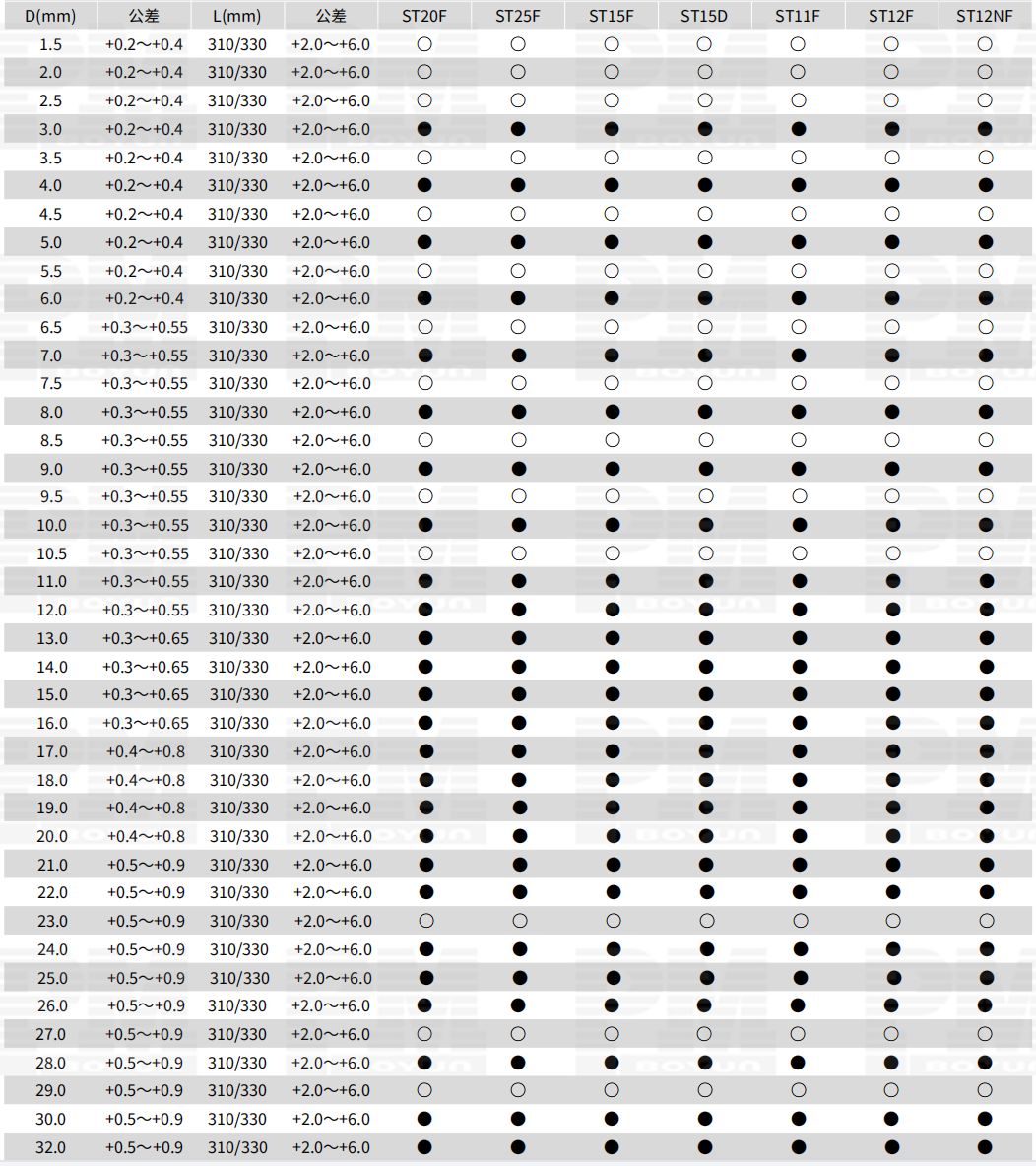

Common Sizes

Grade List

| Grade Introduction to Carbide Rods | |||||||

| Grade | Co % | WC grain size | HRA | HV | Density (g/cm³) | Bending strength(MPa) | Fracture toughness(MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| KT10UF | 6 | superfine | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| KT10C | 7 | Fine | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| KT11UF | 8 | superfine | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | superfine | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | superfine | 92.4 | 1740 | 14.1 | 5100 | 10 |

| KT25EF | 12 | superfine | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | superfine | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

For further information (MOQ, price, delivery) or if you need customization services, please request a quote.