Products

Tungsten cemented carbide button inserts for milling bits

Product Introduction

We produce Button bits in tungsten carbide with various types. Carbide buttons are widely used in oil filed drilling, because of its high stength and good wear resistance. Based on the different functions,the carbide buttons has been devide into many styles,they often applied in Roller Cone Bits, Geotechnical Drilling Tools, DTH Bits, Drifter Bits.Our quality is stable and good.

advantage

1. 100% raw material tungsten carbide.

2. Sintered in HIP furnace

3. ISO9001: 2015 certificate.

4. Fully adopted in advance technology and equipment.

5. Professional manufacturer for tungsten carbide items over 10 years experience.

6. Quality Control System and strict inspection.

7. OEM and ODM are accepted as well.

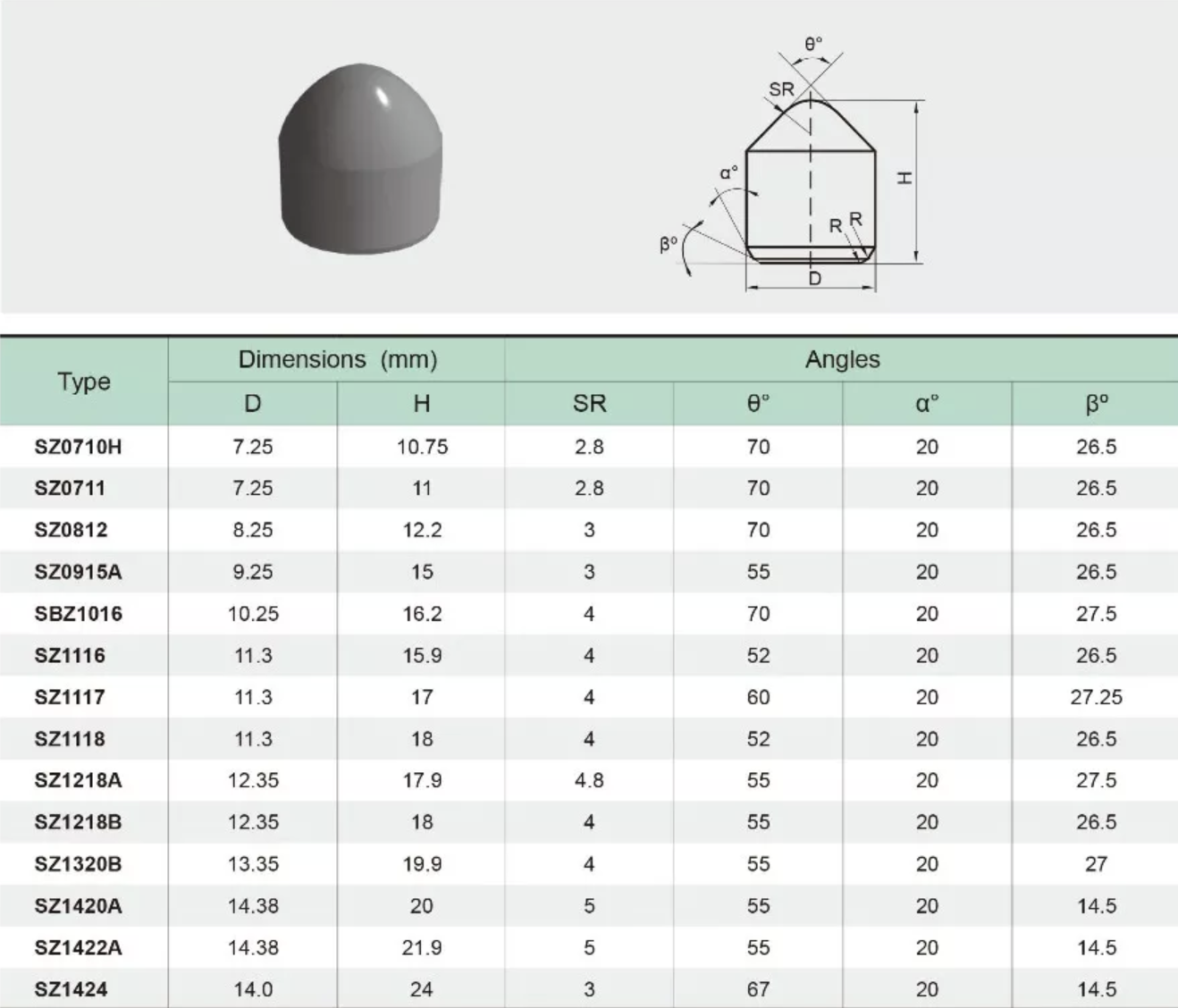

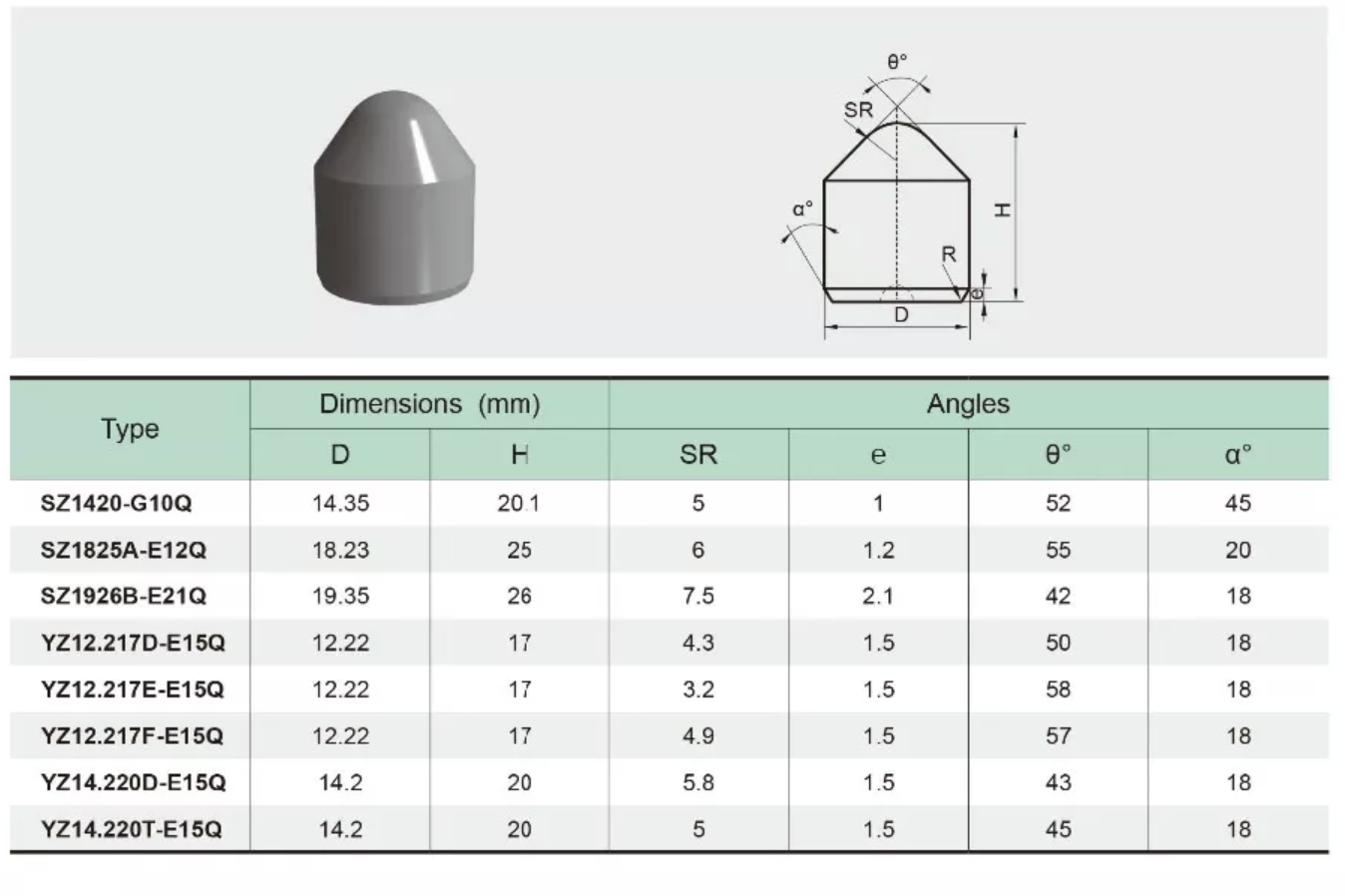

Detail drawing

Grade for Reference

| Grade | Density | TRS | Hardeness HRA | Applications |

| g/cm3 | MPa | |||

| YG4C | 15.1 | 1800 | 90 | It is mainly used as an impact drill for cutting soft, medium and hard materials |

| YG6 | 14.95 | 1900 | 90.5 | Used as electronic coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

| YG8 | 14.8 | 2200 | 89.5 | Used as core drill, electric coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

| YG8C | 14.8 | 2400 | 88.5 | It is mainly used as the ball tooth of small and medium-sized impact bit and as the bearing bush of rotary exploration drill. |

| YG11C | 14.4 | 2700 | 86.5 | Most of them are used in impact bits and ball teeth used to cut high hardness materials in cone bits. |

| YG13C | 14.2 | 2850 | 86.5 | It is mainly used for cutting ball teeth of medium and high hardness materials in rotary impact drill. |

| YG15C | 14 | 3000 | 85.5 | It is a cutting tool for oil cone drill and medium soft and medium hard rock drilling. |

Reference Dimensions