Products

Tungsten Carbide Drilling Button

Product Introduction

The Carbide Inserts, Compacts Buttons for the Tricone bits, roller bits are usually be of very good thoughess and wear resistance, we make them from high quality virgin materials and sepcially treat them in the course of production.

Product Features

1. promise the 100% virgin material .

2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

3. suply blank and surface passivation.

4. tungsten carbide button's high hardness of the cemented carbide and other characteristics are widely used in mining and quarrying and cutting process, also may be placed on a heavy excavators used in bit.

5. we can product the goods according your drawing and sizes.

6. our new product grade's grain size can up to 6.0μm,highest wear-resisting and excellentest impact resistance.

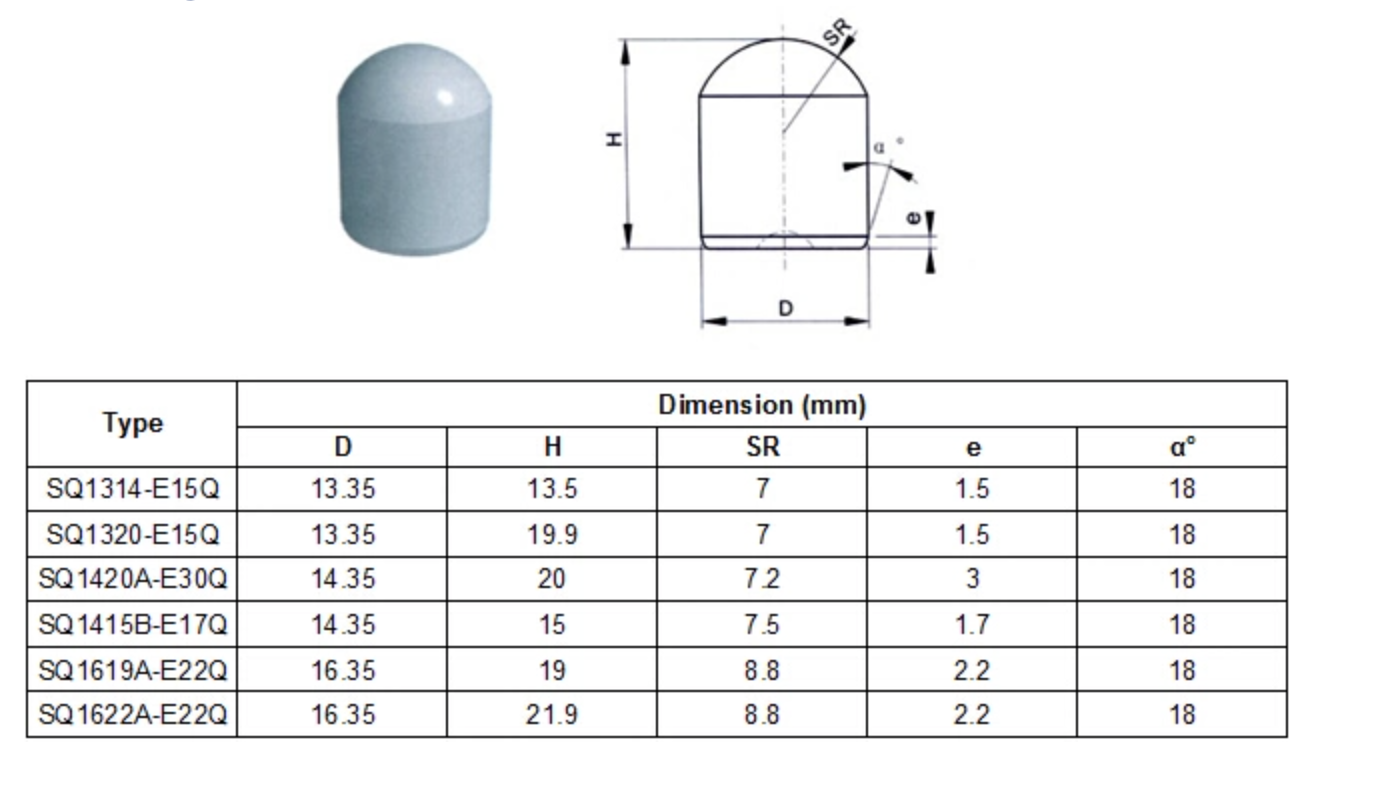

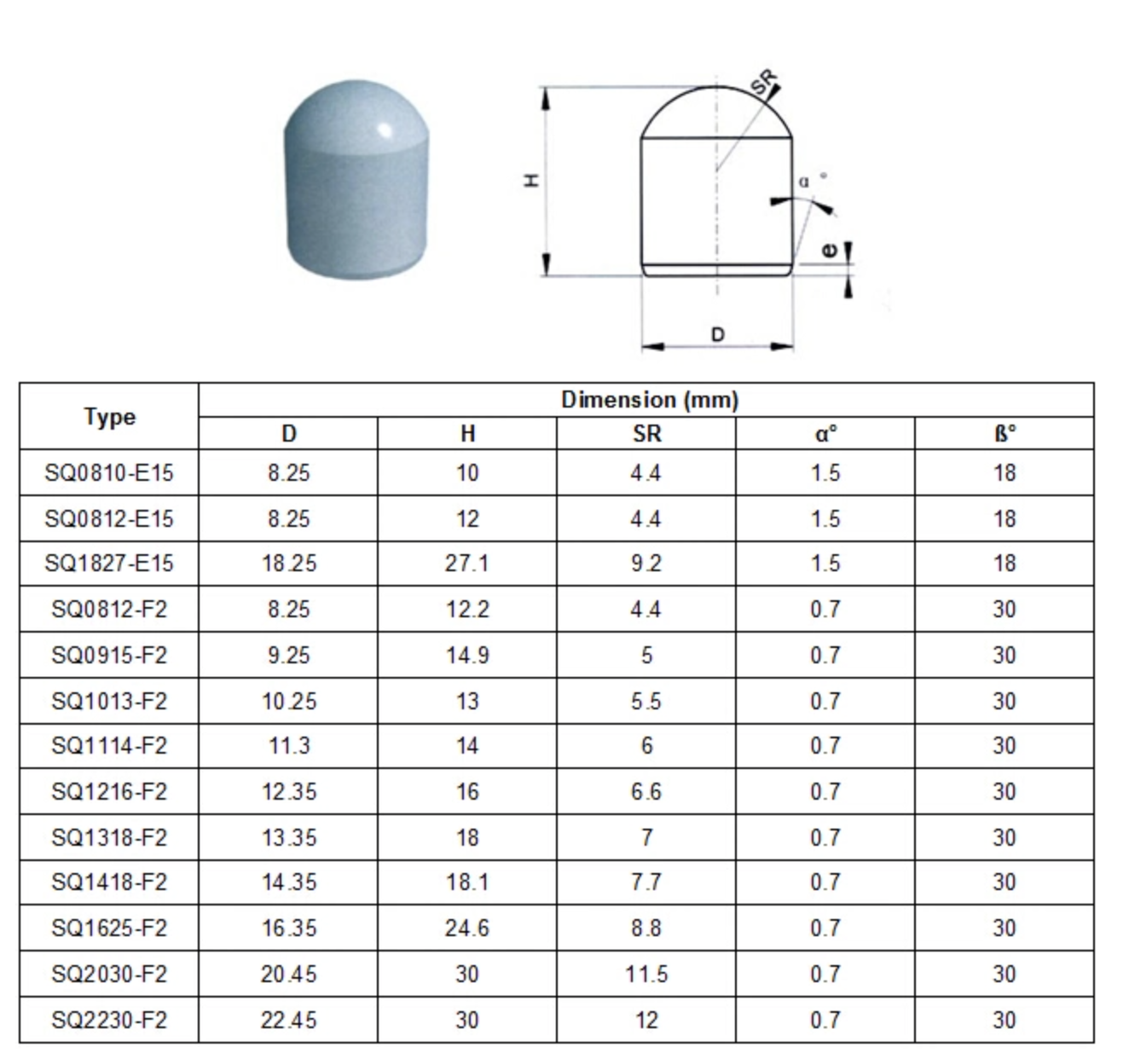

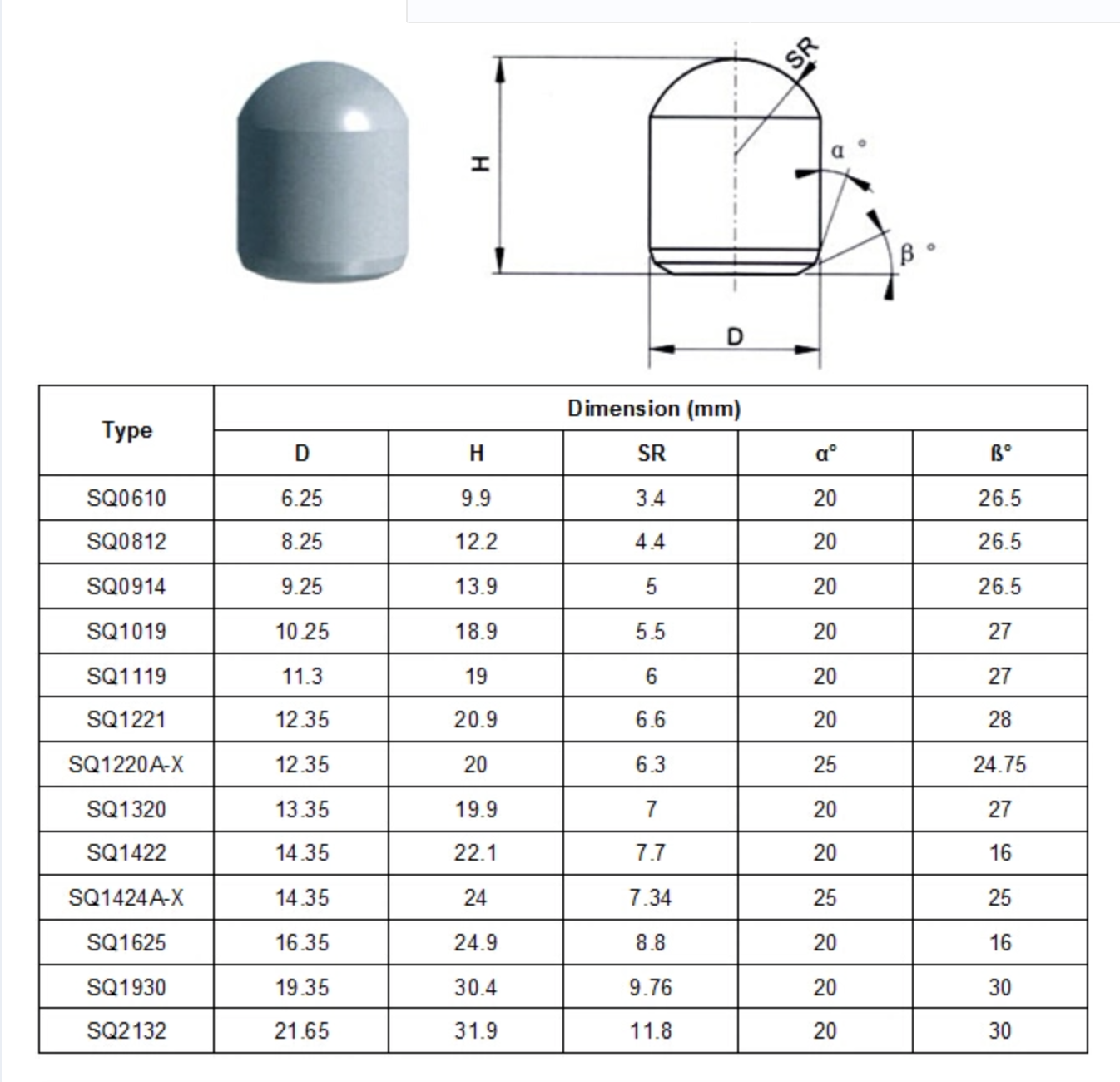

Detail drawing

Material Grade Chart

| Grade | Density | TRS | Hardeness HRA | Applications |

| g/cm3 | MPa | |||

| YG4C | 15.1 | 1800 | 90 | It is mainly used as an impact drill for cutting soft, medium and hard materials |

| YG6 | 14.95 | 1900 | 90.5 | Used as electronic coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

| YG8 | 14.8 | 2200 | 89.5 | Used as core drill, electric coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

| YG8C | 14.8 | 2400 | 88.5 | It is mainly used as the ball tooth of small and medium-sized impact bit and as the bearing bush of rotary exploration drill. |

| YG11C | 14.4 | 2700 | 86.5 | Most of them are used in impact bits and ball teeth used to cut high hardness materials in cone bits. |

| YG13C | 14.2 | 2850 | 86.5 | It is mainly used for cutting ball teeth of medium and high hardness materials in rotary impact drill. |

| YG15C | 14 | 3000 | 85.5 | It is a cutting tool for oil cone drill and medium soft and medium hard rock drilling. |

Common reference dimensions