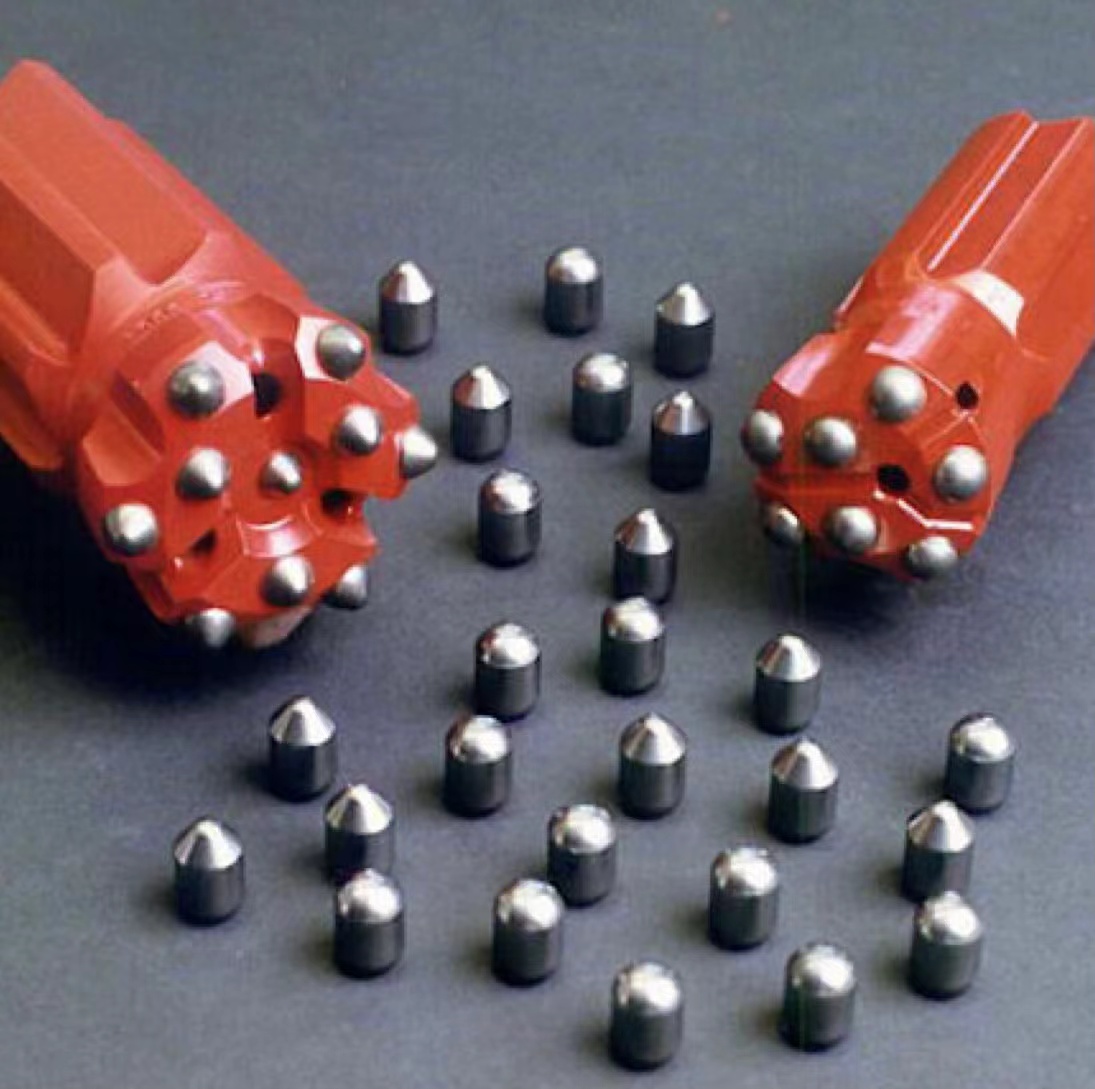

Products

Tungsten Carbide Buttons for Rock Bits

Advatages

1. Manufactured with the highest quality carbide for stable & consistent quality.

2. Processing with latest manufacturing technology HIP sintered to produce ultimate in quality.

3. Strict quality checking accompany the overall production process to ensure every batch of product meet customers' standard before being put on the market.

4. A wide range of tungsten carbide grade and size for selection.

5. Factory-direct shipment ensure short delivery time.

6. We also offer experienced advice to help you produce the best possible product at the lowest possible cost.

7. Customised carbide buttons are available, etc.

Production Process

Milling--Proportioning as required--Wet grinding--Dry--Granulation--Press--Sinter--Inspection--Package

Detail drawing

Grade for Reference

| Grade | Density | TRS | Hardeness HRA | Applications |

| g/cm3 | MPa | |||

| YG4C | 15.1 | 1800 | 90 | It is mainly used as an impact drill for cutting soft, medium and hard materials |

| YG6 | 14.95 | 1900 | 90.5 | Used as electronic coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

| YG8 | 14.8 | 2200 | 89.5 | Used as core drill, electric coal bit, coal pick, petroleum cone bit and scraper ball tooth bit. |

| YG8C | 14.8 | 2400 | 88.5 | It is mainly used as the ball tooth of small and medium-sized impact bit and as the bearing bush of rotary exploration drill. |

| YG11C | 14.4 | 2700 | 86.5 | Most of them are used in impact bits and ball teeth used to cut high hardness materials in cone bits. |

| YG13C | 14.2 | 2850 | 86.5 | It is mainly used for cutting ball teeth of medium and high hardness materials in rotary impact drill. |

| YG15C | 14 | 3000 | 85.5 | It is a cutting tool for oil cone drill and medium soft and medium hard rock drilling. |