Products

ODM Manufacturer Gw Carbide

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for ODM Manufacturer Gw Carbide, We attend seriously to produce and behave with integrity, and from the favor of consumers at home and abroad within the xxx industry.

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Tungsten Carbide Bclv Nozzle/Boron Carbide Nozzle with Aluminum Jacket, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!

Production Introduction

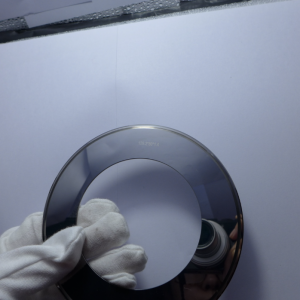

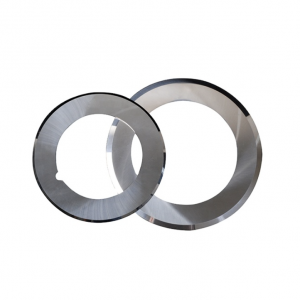

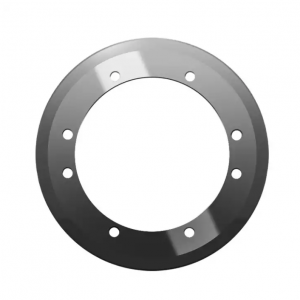

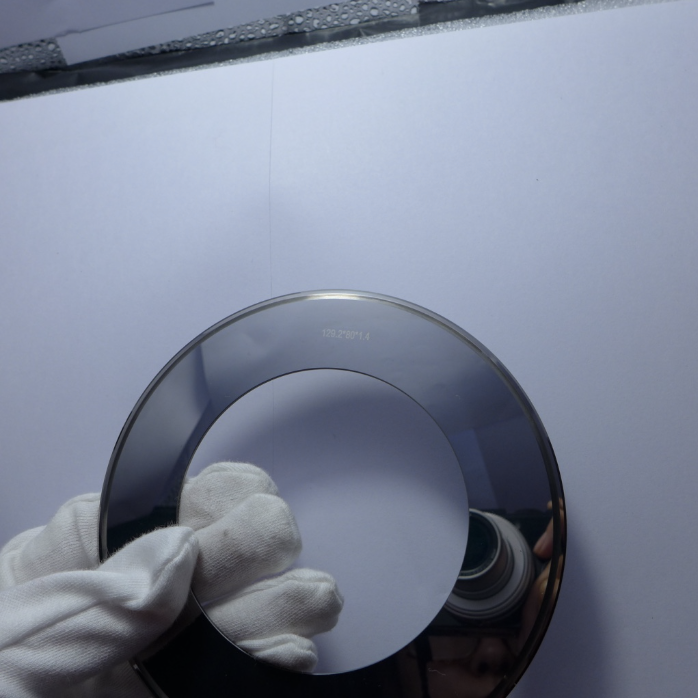

The new energy series alloy lithium battery electrode continuous slitting knife is made of cemented carbide powder by pressing and sintering, which has the characteristics of high hardness, strong wear resistance, anti sticking knife and so on. It specializes in solving all kinds of bad phenomena such as sticking knife, dust, burr, knife back print, wavy edge, color difference and so on. The full inspection blade is enlarged by 500 times without notch. During the slitting process of the positive and negative plates of lithium battery blade, the edge collapse and burr caused by the poor quality of the slitting edge will cause the battery short circuit problem and form a serious safety hazard. Chengdu Kedel Tools Co., Ltd. has many years of experience in the production of cemented carbide industrial tools. All alloy blanks are produced by ourself, and has a deep understanding of the grinding and processing of alloy tools. Adhering to the spirit of “craftsman”, strictly control the dimensional tolerance of the blade. The unique cutting edge precision processing technology and 100% cutting edge automatic equipment full inspection process ensure the excellent performance of the lithium battery pole slice slitter.

Product Features

1. Hard alloy tungsten steel material, with strong wear resistance;

2. The cutting edge has high machining accuracy, and the thickness accuracy can reach 3 microns;

3. Long service life, less tool change, high cost performance, cutting length up to 20000 meters;

4. The outer circle of the blade has good consistency, the blade edge is strictly enlarged, and there is no curling during detection, and the burr is small;

5. It is mainly used for cutting non-ferrous metals such as lithium battery pole piece, ceramic diaphragm, copper foil, aluminum foil, etc;

6.The blades are divided into upper knife group and lower knife group, which are used in complete sets.

Material

|

Grade |

Grain Size |

Density (g/cm³) |

HRA |

Fracturetoughness (kgf/mm²) |

TRS(MPa) |

|

KS26D |

sub-fine |

14.0-14.1 |

90.4-90.8 |

19-20 |

4000-4800 |

Main specifications and dimensions

|

Common Sizes |

||||

|

NO. |

Product Name |

Dimentions(mm) |

Edge angle |

Applicable cutting materials |

|

1 |

Slitting top knife |

Φ100xΦ65×0.7 |

26°、30°、35°、45° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ100xΦ65×2 |

26°、30°、35°、45°90° |

||

|

2 |

Slitting top knife |

Φ100xΦ65×1 |

30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ100xΦ65×3 |

90° |

||

|

3 |

Slitting top knife |

Φ110xΦ90×1 |

26°、30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ110xΦ75×3 |

90° |

||

|

4 |

Slitting top knife |

Φ110xΦ90×1 |

26°、30° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ110xΦ90×3 |

90° |

||

|

5 |

Slitting top knife |

Φ130xΦ88×1 |

26°、30°、45°90° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ130xΦ70×3/5 |

90° |

||

|

6 |

Slitting top knife |

Φ130xΦ97×0.8/1 |

26°、30°、35°45° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ130xΦ95×4/5 |

26°、30°、35°、45°90° |

||

|

7 |

Slitting top knife |

Φ68xΦ46×0.75 |

30°、45°、60° |

Lithium battery pole piece |

|

Slitting bottom knife |

Φ68xΦ40×5 |

90° |

||

|

8 |

Slitting top knife |

Φ98xΦ66×0.7/0.8 |

30°、45°、60° |

Ceramic diaphragm |

|

Slitting bottom knife |

Φ80xΦ55×5/10 |

3°、5° |

||

|

NOTE: Customization available per customer drawing or actual sample |

||||

Product Details

Application Scenario

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for ODM Manufacturer Gw Carbide, We attend seriously to produce and behave with integrity, and from the favor of consumers at home and abroad within the xxx industry.

ODM Manufacturer Tungsten Carbide Bclv Nozzle/Boron Carbide Nozzle with Aluminum Jacket, You can do one-stop shopping here. And customized orders are acceptable. Real business is to get win-win situation, if possible, we would like to provide more support for customers. Welcome all nice buyers communicate details of products and ideas with us!!