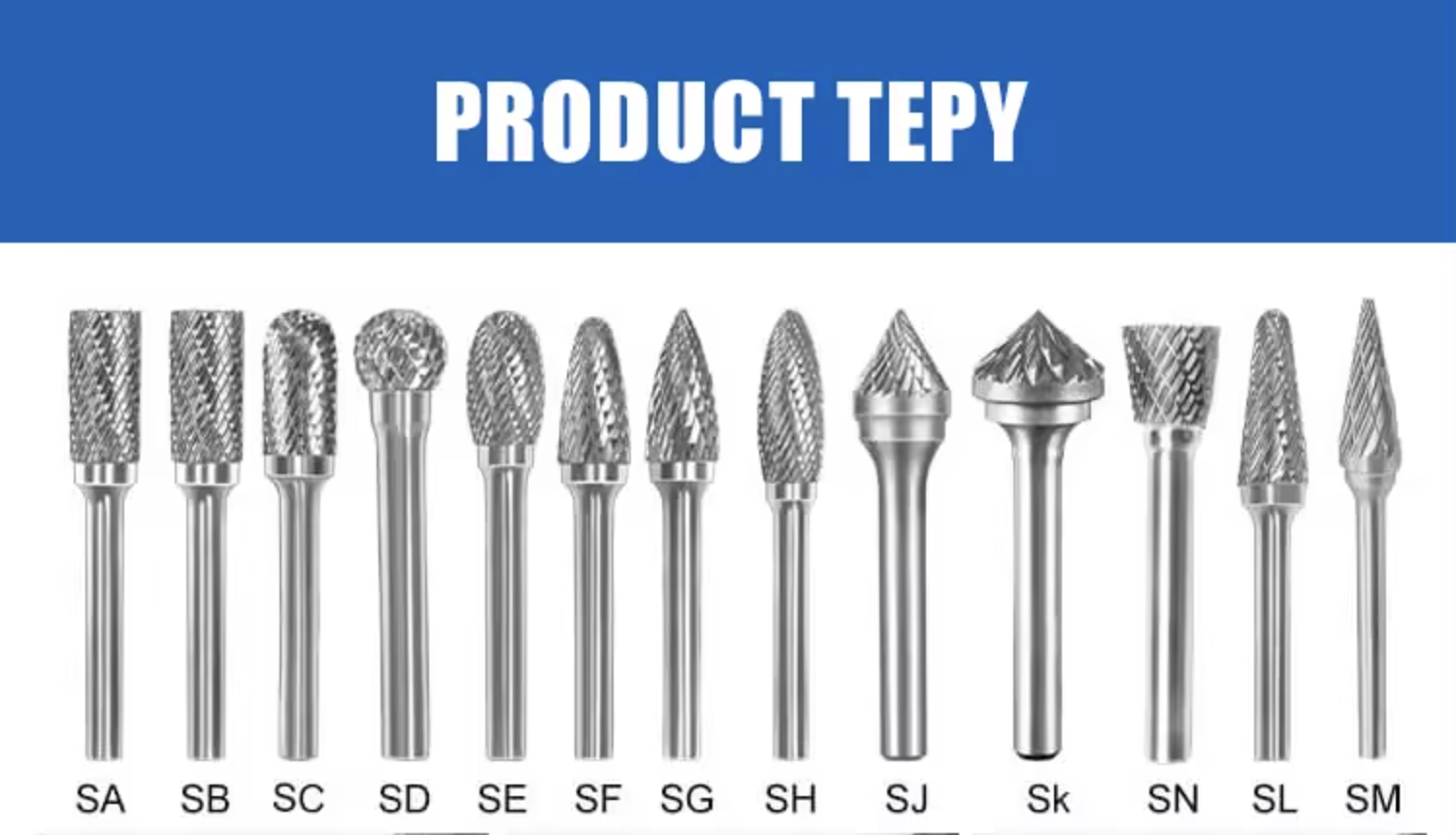

Tungsten carbide rotary files are a common metal processing tool, available in many types, widely used in mechanical processing, automobile repair, aerospace and other fields. This article will introduce the applications of different types of alloy rotary files, as well as their role and value in various fields.

Application of steel carbide rotary files in machining

Steel alloy burrs are the most common type and are typically used for precision machining of metal parts. In the field of machining, steel alloy rotary files can be used for trimming, smoothing and removing burrs from metal surfaces to ensure the accuracy and surface quality of parts. Its wear resistance and durability make it an indispensable tool in machining.

Application of tungsten carbide alloy rotary files in automobile maintenance

Tungsten carbide alloy rotary files have higher hardness and wear resistance and are suitable for processing hard materials. In the field of automobile maintenance, tungsten carbide alloy rotary files are often used to trim engine parts, wheel bearings and other metal parts. They can quickly remove surface burrs, improve the accuracy and quality of parts, and ensure the safety and reliability of automobiles.

Application of titanium alloy rotary files in aerospace field

Titanium alloy rotary files have excellent corrosion resistance and high temperature performance, and are suitable for processing titanium alloy parts. In the aerospace field, titanium alloy rotary files are often used to trim aircraft engine parts, spacecraft structural parts, etc., which can effectively remove surface defects, improve the accuracy and surface quality of parts, and ensure the reliability and safety of aerospace devices.

Application of stainless steel alloy rotary files in medical device manufacturing

Stainless steel alloy rotary files have good corrosion resistance and hygiene, and are suitable for the processing and manufacturing of medical devices. In the field of medical device manufacturing, stainless steel alloy rotary files are often used to trim surgical instruments, implantation instruments, etc., which can ensure the smoothness and precision of the surface of the instrument and ensure the safety and hygiene of the medical device.

Steel alloy rotary files ensure the accuracy and surface quality of parts in machining; tungsten carbide alloy rotary files improve the accuracy and reliability of parts in automobile maintenance; titanium alloy rotary files ensure the quality of aerospace devices in the aerospace field Reliability and safety; stainless steel alloy rotary files ensure the hygiene and safety of instruments in medical device manufacturing. Different types of alloy rotary files play an important role in their respective fields and provide strong support for the development of various industries.

Post time: Feb-19-2024