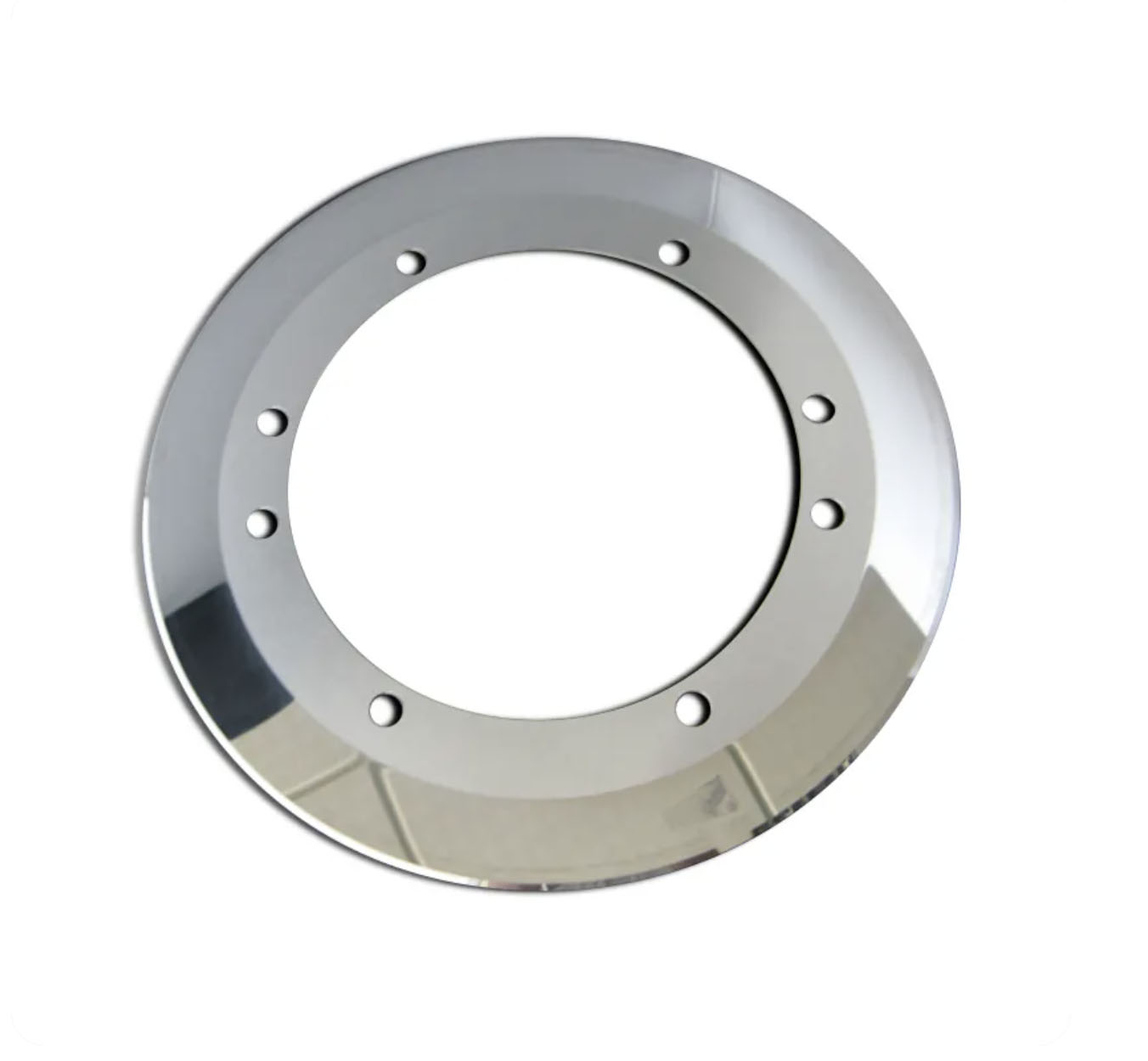

Tungsten carbide circular knives are widely used in various industries for cutting and machining purposes. They are commonly used in the cutting and shaping of various materials such as wood, plastics, rubber, and textiles. Tungstn carbide circular knives are also frequently utilized in the metalworking industry for cutting and slitting operations in applications such as metal sheet cutting, pipe cutting, and metal component machining. Additionally, they find applications in the paper industry for cutting and trimming paper products. Moreover, they are employed in the field of printing for cutting and trimming paper and cardboard materials. Other applications include leather cutting and shaping, foam cutting, and cutting of other soft or hard materials. Overall, tungsten carbide circular knives are versatile cutting tools used in a diverse range of industries and applications.

Now let’s focus on introducing the main application areas of the circular knives produced by Kedel Tool.

1,For Paper Cutting

Tungsten carbide circular knives are widely used for cutting corrugated cardboard due to their specific characteristics and advantages. These knives are known for their high hardness and wear resistance, allowing them to withstand the demanding cutting conditions involved in the corrugated cardboard industry. They have a sharp cutting edge that can effortlessly slice through the layers of corrugated board, delivering clean and precise cuts. The high strength of the hard alloy circular knives ensures that they remain durable and long-lasting, even with continuous use. Additionally, these knives provide excellent cutting efficiency, reducing the time and effort required for the cutting process. The superior heat resistance of hard alloy circular knives prevents them from overheating during prolonged use, ensuring consistent cutting performance. Another notable advantage is their low maintenance requirements, contributing to cost savings and operational efficiency. Overall, the unique characteristics of hard alloy circular knives make them an ideal choice for cutting corrugated cardboard, offering reliable performance, durability, and improved productivity.

2,For cigarette Industry Cutting

Tungsten carbide circular knives are also highly advantageous for cutting in the tobacco industry. With their exceptional hardness and wear resistance, these knives can withstand the demanding cutting conditions involved in cigarette production. They offer sharp cutting edges that effortlessly slice through tobacco leaves, resulting in clean and precise cuts. Their durability ensures long-lasting performance, reducing maintenance costs. Hard alloy circular knives also provide excellent cutting efficiency, enhancing productivity. Their heat resistance prevents overheating during prolonged use, ensuring consistent performance. Overall, these knives are a reliable and efficient choice for cutting in the cigarette industry.

3,For Lithium battery cutting industry

Cemented carbide circular knives are widely used in the lithium battery cutting industry due to their excellent application and distinct characteristics. The knives are highly durable and resistant to wear, making them ideal for the rigorous cutting requirements in battery production. They provide precise and sharp cuts, ensuring high-quality results. The heat resistance of these knives enables them to withstand prolonged use without overheating, guaranteeing continuous and efficient cutting operations. The efficiency and reliability of hard alloy circular knives make them an indispensable tool in the lithium battery cutting industry.

In addition, tungsten carbide circular knives are also widely used in packaging and printing industries, chemical fiber industries, metal cutting, woodworking and other industries. The super wear-resistant and high-temperature resistant properties of hard alloy provide a very good tool material foundation for the industrial field.

Post time: Nov-21-2023