Products

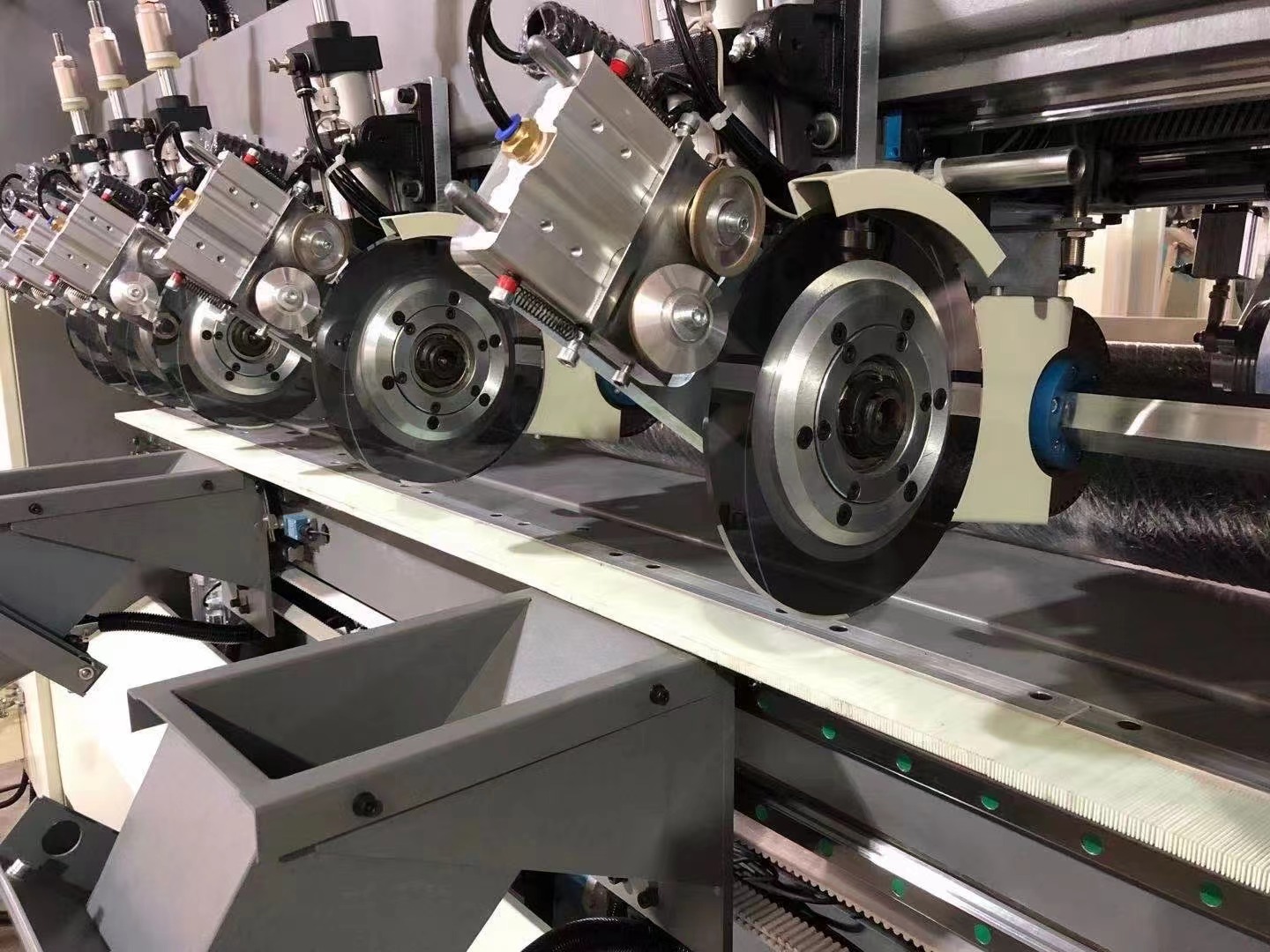

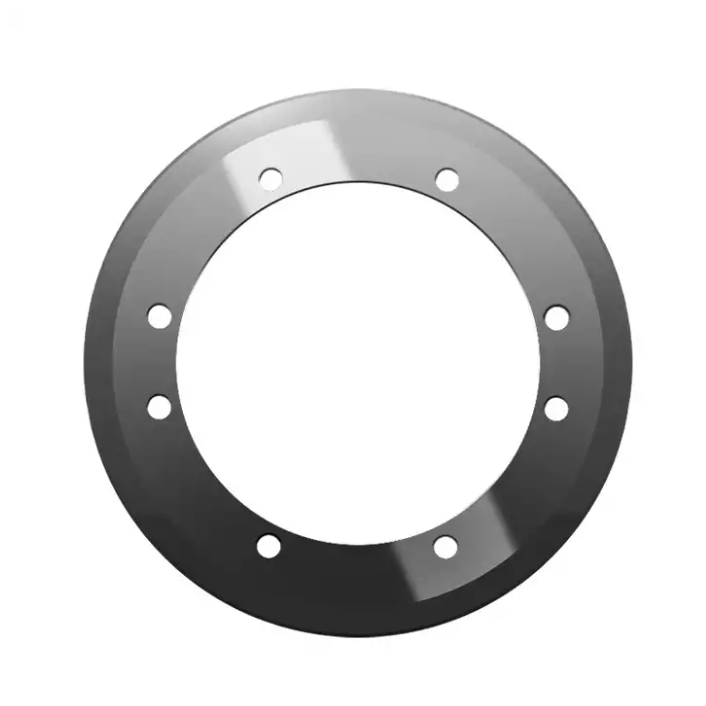

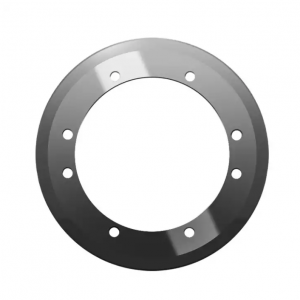

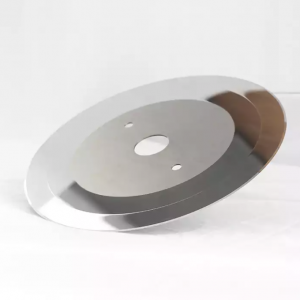

Circular slitting knives blades for corrugated paper board

Product Features

1. Long service life. Low friction coefficient and long service life, each blade detects inbound shipments, ensuring quality without worry.

2. Hardness Guarantee. The raw materials are heat treated, vacuum treated, and the hardness is higher. Heat treatment in your own factory to ensure product stability.

3. Sharp edge. The knife edge is sharp, smooth, sharp and durable, imported precision processing equipment can process a variety of non-standard products to ensure the precision of the products.

Material Grade

|

Grade |

Grain Size |

Density (g/cm³) |

Hardness (HRa) |

T.R.S (N/m㎡) |

Application |

|

YG12X |

Submicron |

13.9-14.3 |

90.8-91.5 |

3200 |

Suitable for processing cardboard |

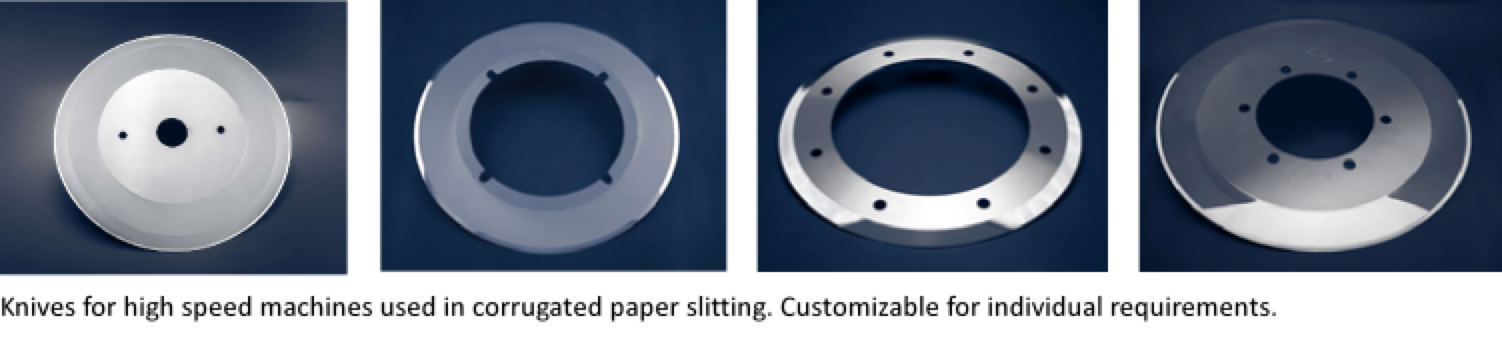

Carbide knives for high-speed machines

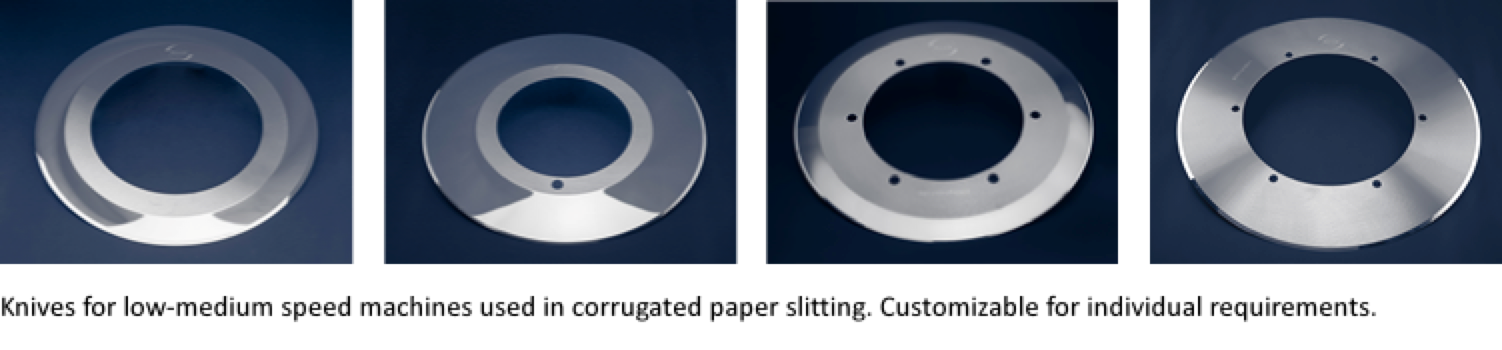

Carbide knives for low-medium speed machines

Common Sizes

|

Dimension(mm) |

OD(mm) |

ID(mm) |

Thickness(mm) |

Machine Brand |

|

Φ300*Φ112*1.2 |

Φ300 |

Φ112 |

1.2 |

TCY |

|

Φ291*Φ203*1.1 |

Φ291 |

Φ203 |

1.1 |

FOSBER |

|

Φ280*Φ202*1.4 |

Φ280 |

Φ202 |

1.4 |

Mitsubishi |

|

Φ280*Φ160*1.0 |

Φ280 |

Φ160 |

1 |

Mitsubishi |

|

Φ280*Φ168*1.4 |

Φ280 |

Φ168 |

1.4 |

K&M |

|

Φ260*Φ168.3*1.2 |

Φ260 |

Φ168 |

1.2 |

Marquip |

|

Φ260*Φ140*1.5 |

Φ260 |

Φ140 |

1.5 |

lsowa |

|

Φ265*Φ112*1.4 |

Φ265 |

Φ112 |

1.4 |

Oranda |

|

Φ260*Φ112*1.4 |

Φ260 |

Φ112 |

1.4 |

Oranda |

|

Φ260*Φ168.27*1.2 |

Φ260 |

Φ168.27 |

1.2 |

Hooper/Simon |

|

Φ250*Φ150*0.8 |

Φ250 |

Φ150 |

0.8 |

Peters |

|

Φ244*Φ222*1.0 |

Φ244 |

Φ222 |

1 |

Hooper |

|

Φ240.18*Φ31.92*1.14 |

Φ240.18 |

Φ31.92 |

1.14 |

BHS |

|

Φ240*Φ32*1.2 |

Φ240 |

Φ32 |

1.2 |

BHS |

|

Φ240*Φ115*1.0 |

Φ240 |

Φ115 |

1 |

Agnati |

|

Φ230*Φ110*1.1 |

Φ230 |

Φ110 |

1.1 |

FOSBER |

|

Φ230*Φ135*1.1 |

Φ230 |

Φ135 |

1.1 |

FOSBER |

| Knife edge type: Single or double side available. | ||||

| Materials: Tungsten Carbide or customization Materials. | ||||

| Application: For corrugated paperboard industry, for cutting tobacco, paper cutting, film, foam, rubber,foil, graphite and so on. | ||||

| NOTE: Customization available per customer drawing or actual sample | ||||

Application