Products

Cemented Tungsten Carbide Sleeves Bushings For Submersibe Oil Field

Product Introduction

Tungsten carbide sleeve applications is wide, which is a device to protect a class of components. It is in the actual work and the role and purpose of its application environment have a great relationship.

Valve applications, bushings be installed in the valve stem cap trap, in order to reduce the valve leakage, to seal; bearing applications, the use of bush to reduce wear between the bearing and the shaft seat, avoid the gap between the shaft and the hole increases and so on.

Tungsten carbide sleeve production and processing of high-strength, can withstand prolonged load, with high chemical stability, alkali, alcohol, ether, hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics, its widely used in petrochemical industry for Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

advantages

1, 100% Raw material:

Bushings are produced with pure raw materials, which has the characteristics of long service life and stable performance.

2, Maching:

Bushings is processed by high-precision equipment:CNC machining center, grinding machine, milling machine, drilling machine,horizontal milling machine, chamfering machine, Metal Stamping ,CNC cutting machine etc.

3, Multiple sizes available:

We can provide bearing bushings different sizes, complete molds and short delivery time.7-10 days for samples .20-25 working days for mass productions

4,Quality assurance:

Unsurpassed Quality Standards.Our bushings sleeves bearings are designed and manufactured according to stringent quality standards that govern material selection, machining, surface finishing,inspection and packaging.

Exhibit

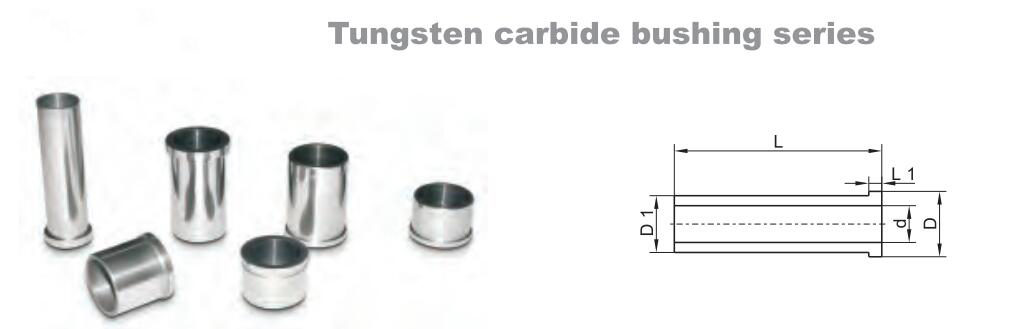

Detail drawing

Material table

| Grade | ISO | Specification | Application of tungsten carbide | ||

| Density | TRS | Hardness | |||

| G/Cm3 | N/mm2 | HRA | |||

| YG06X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG06 | K20 | 14.7-15. 1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG08 | K20-K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, non-metal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG09 | K30-M30 | 14.5-14.8 | ≥2300 | ≥91.5 | Qualified for low speed rough machining, milling titanium alloy and refractory alloy, especially for cut-off tool and silk prick. |

| YG11C | K40 | 14-.3-14.6 | ≥2100 | ≥86.5 | Qualified for molding the drills for heavy-duty rock drill: detachable bits used for deep hole drilling, rock drill trolley etc. |

| YG15 | K40 | 13.9-14.1 | ≥2020 | ≥86.5 | Qualified for hard rock drilling, steel bars with high compression ratios, pipe drawing, punching tools, core cabinet of powder metallurgy automatic molders etc. |

| YG20 | 13.4-14.8 | ≥2480 | ≥83.5 | Qualified for making dies with low impact such as punching watch parts, battery shells, small screw caps etc. | |

| YG25 | 13.4-14.8 | ≥2480 | ≥82.5 | Qualified for making mould of cold heading, cold stamping and cold pressing used for manufacturing standard parts, bearings etc. | |

Dimension table

| Model No. | Specification | OD(D:mm) | ID(D1:mm) | Pore(d:mm) | Length(L:mm) | Step length(L1:mm) |

| KD-2001 | 01 | 16.41 | 14.05 | 12.70 | 25.40 | 1.00 |

| KD-2002 | 02 | 16.41 | 14.05 | 12.70 | 31.75 | 1.00 |

| KD-2003 | 03 | 22.04 | 18.86 | 15.75 | 31.75 | 3.18 |

| KD-2004 | 04 | 22.04 | 18.86 | 15.75 | 50.80 | 3.18 |

| KD-2005 | 05 | 16.00 | 13.90 | 10.31 | 76.20 | 3.18 |

| KD-2006 | 06 | 22.00 | 18.88 | 14.30 | 25.40 | 3.18 |

| KD-2007 | 07 | 24.00 | 21.00 | 16.00 | 75.00 | 3.00 |

| KD-2008 | 08 | 22.90 | 21.00 | 15.00 | 75.00 | 3.00 |

| KD-2009 | 09 | 19.50 | 16.90 | 12.70 | 50.00 | 4.00 |

| KD-2010 | 10 | 36.80 | 32.80 | 26.00 | 55.00 | 4.00 |