Products

1/4” (6mm) Shank Tungsten carbide rotary burrs

Production Description

Cemented carbide rotary file, also known as cemented carbide high-speed assorted milling cutter, cemented carbide die milling cutter, etc., is used together with high-speed electric mill or pneumatic tools. Cemented carbide rotary file is widely used in machinery, automobile, ship, chemical industry, craft carving and other industrial sectors. Hard alloy rotary file can be used to process cast iron, cast steel, carbon steel, alloy steel, stainless steel, hardened steel, copper and aluminum, etc. As the cemented carbide rotary file is clamped on a high-speed rotating tool for manual control, the pressure and feed speed of the cemented carbide rotary file depend on the service life and cutting effect of the tool.

Advatages

1. It can process cast iron, cast steel, carbon steel, alloy steel, stainless steel, copper, aluminum and other metals, and marble, jade, bone and other nonmetals. The processing hardness can reach HRA ≥ 85.

2. It can basically replace the small grinding wheel with handle, and has no dust pollution.

3. High production efficiency. The processing efficiency is dozens of times higher than that of manual file and nearly ten times higher than that of small grinding wheel with handle.

4. Good processing quality and high finish. It can process various high-precision mold cavities.

5. Long service life. The durability is 10 times higher than that of high-speed steel cutter and 200 times higher than that of small grinding wheel.

6. Easy to master, simple to use, safe and reliable.

7. The comprehensive processing cost can be reduced dozens of times.

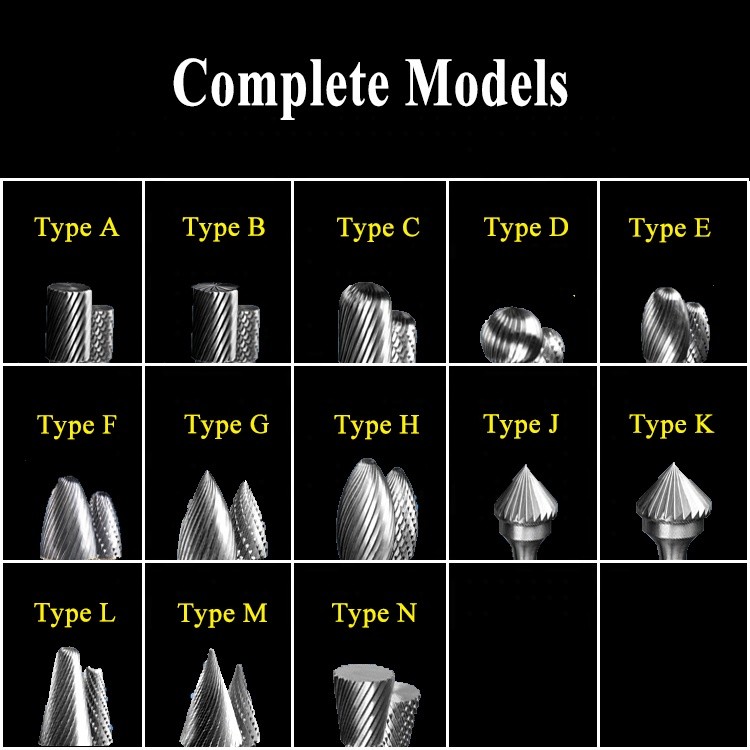

Main Types

Shape A Cylindrical Plan End

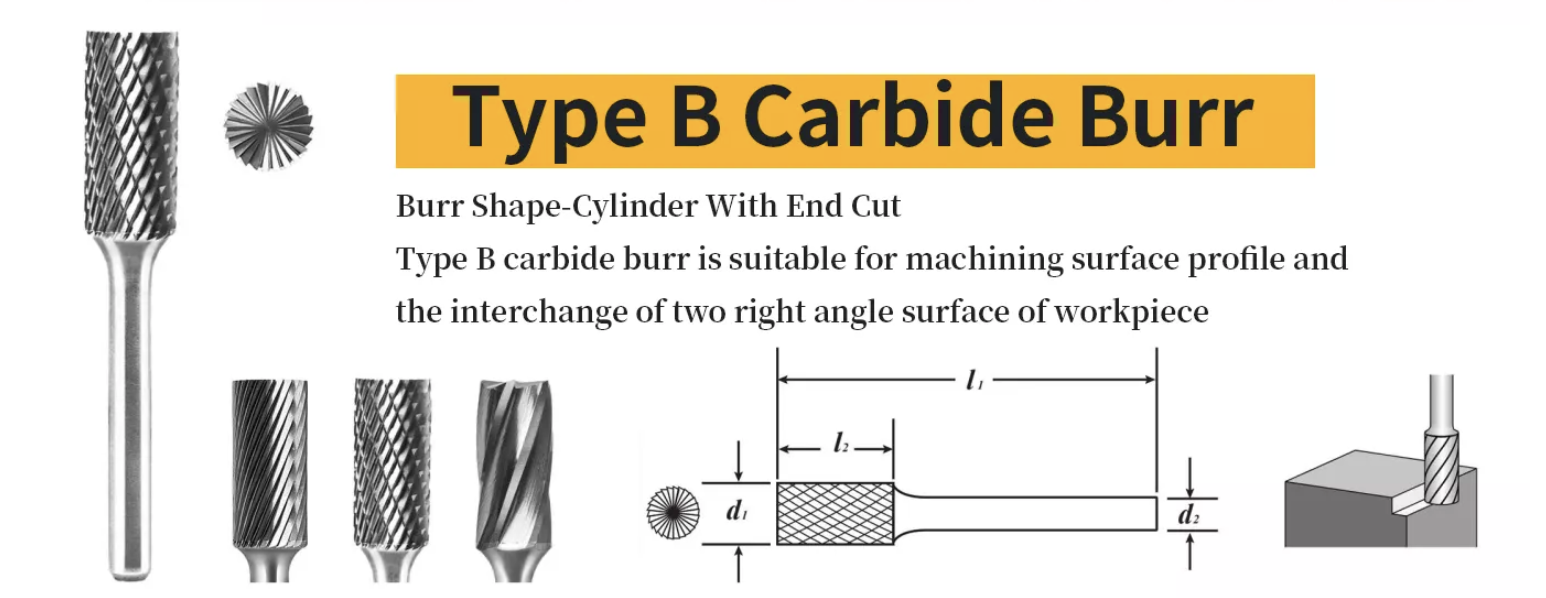

Shape B Cylindrical End Cut

Shape C Cylindrical Ball Nose

Shape D Ball Shape

Shape E Oval Shape

Shape F Tree Radius End

Shape G Point Tree Shape

Shape H Flame Shape

Shape J 60-degree countersink

Shape K 90-degree countersink

Shape L Cone Radius End

Shape M Cone Pointed Shape

Shape N Inverted Cone

Main Sizes

|

Metric Size |

||||||

|

Shank Diameter(mm) |

Cutter Diameter(d1) |

Length of Cut(l2) |

Shank Diameter(d2) |

Overall Length(L1) |

Tool No. |

Type |

|

6.0 |

6 |

16 |

6 |

50 |

B60616 |

solid |

|

6 |

16 |

6 |

61 |

B60616 |

brazed |

|

|

8 |

20 |

6 |

65 |

B60820 |

brazed |

|

|

10 |

20 |

6 |

65 |

B61020 |

brazed |

|

|

11 |

20 |

6 |

70 |

B61125 |

brazed |

|

|

12 |

25 |

6 |

70 |

B61225 |

brazed |

|

|

16 |

25 |

6 |

70 |

B61625 |

brazed |

|

|

20 |

25 |

6 |

70 |

B62025 |

brazed |

|

|

25 |

25 |

6 |

70 |

B62525 |

brazed |

|